Together, exploring a new era of woodworking innovation. This is the concept behind the event taking place at the SCM Headquarters in Rimini from 12 to 14 March 2026. Driving the future of woodworking through the integration of advanced technologies, proactive services and digital innovation: this is the goal of the upcoming SCM Open House, scheduled for March 12 – 14, 2026 at SCM Headquarters in Rimini.

Across more than 4,000 square meters, visitors will be able to explore a wide range of machines, automated systems, software and services designed to support the production of every component of the home – from furniture to timber construction, from surface treatment to flooring, from wooden windows and doors to wood/aluminum solutions.

A series of innovations will immerse attendees in a new era of woodworking innovation, where competitive advantage is no longer defined solely by a single machine or system, but by the ability to integrate them into connected, flexible and sustainable production models. Fully embracing this vision, SCM reaffirms its role as a strategic partner for companies aiming for global competitiveness in a rapidly evolving industry characterized by new materials, faster production cycles and increasing customization.

The Open House will feature a rich programme of live technical demonstrations, guided tours of SCM’s Rimini production plants, live links with other Italian facilities, and dedicated insights into the latest technological and market trends. In addition to an expanded range of SCM products and services, particular interest will also be drawn by strategic partnerships with the Group’s newest companies: Tecno Logica, focused on integrated systems and robotics, and Mecal Machinery, specialised in aluminium, PVC and light-alloy processing.

Digital systems and services

The event will put the spotlight on an Integrated Service Ecosystem designed to provide companies with more efficient production, greater operational control, and continuous manufacturing uptime, thanks to technologies that transform machine-generated data into actionable support. At the core of this modular architecture is WinMES, SCM’s Manufacturing Execution System engineered in partnership with Tecnest, a key player in production planning and supply chain management software.

WinMes is the true digital brain of the factory. By integrating and interpreting real-time data, it optimizes production flows, speeds up operational decision-making, and enhances overall plant reliability. Factory intelligence is further strengthened by Smart Spindle, the advanced spindle-sensor system that enables predictive analysis and helps prevent unplanned machine downtime. To safeguard the entire ecosystem, SCM incorporates advanced Cybersecurity solutions, ensuring protection for data, processes, and infrastructure.

Starting in 2026, all new SCM machines will come equipped with Additional Care, a program that provides comprehensive protection through extended warranty on spare parts and technical support, along with a 3-year maintenance plan. The result: a more stable, secure, and performance-driven production environment, ready to meet the company’s goals.

Automation and integrated machining cells

At Rimini Headquarters an Integrated Sizing and Nesting Cell for Batch 1 production will be presented. Combining advanced automation, operational flexibility and reduced energy consumption, the cell is composed of: flexstore hp, the automatic storage system managing all panel formats; gabbiani gt 2 single-blade panel saw; and morbidelli x200 nesting CNC machining center.

Also on display will be stefani cell E, a compact and automated entry-level solution for Batch 1 production. It transforms the edgebanding of squared panels into an efficient and high-quality process. Ideal for small and medium-sized enterprises aiming for high production performance.

The Open House will also feature a dedicated focus on Tecno Logica solutions. As a key company within the Group, Tecno Logica is a benchmark in the field of integrated systems and robotics, offering technologies engineered to support extremely high production capacities – even in highly diversified and complex scenarios. Its range of systems is applied across multiple sectors, from woodworking to automotive, and broader industrial applications.

New CNC machining centers

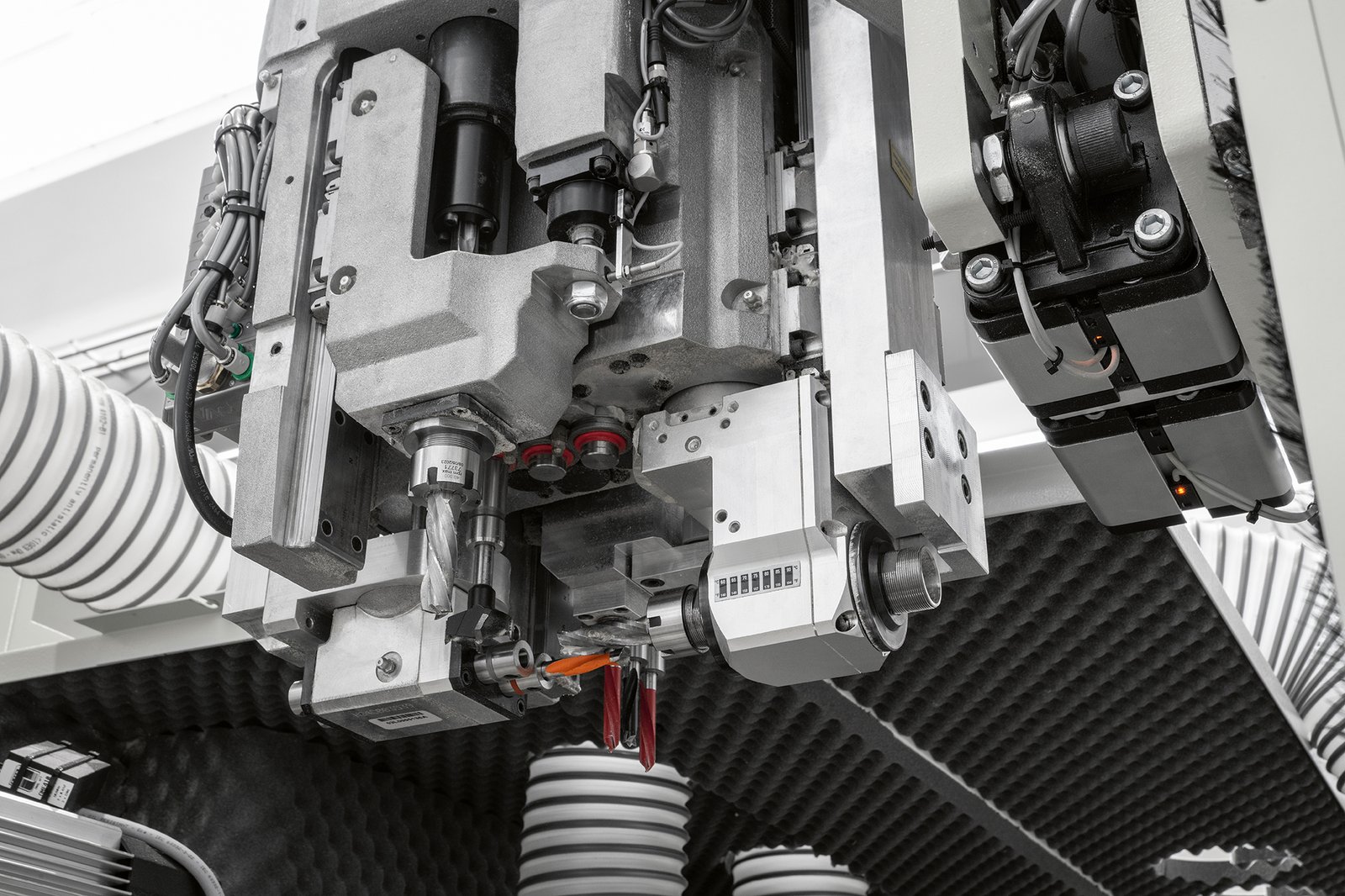

For the accord range, designed for processing both solid wood and panels, two new models will be unveiled. The accord 400 with the new ‘flexmatic pro’ worktable featuring automatic positioning of pods and clamps, it is available in pre-set configurations depending on the application to provide a solution that best suits the customer’s requirements. The accord 500 edge which stands out from the rest of the range thanks to the H80C ‘Compact’ edgebanding technology, which allows operations with various types of edges and glues and enables the automatic change of edge application type. The morbidelli x50 nesting center equipped with lifter integration, a solution that ensures safe and rapid handling of any laminate and chipboard panel, will also be on display.

Panel processing

The event will feature the world premiere of the new gabbiani af beam saw at the Villa Verucchio production plant. The range introduces several key innovations: unrivalled production times thanks to new rapid work cycles, advanced motorization systems, an innovative saw blade carriage with power up to 27 kW, and operational units optimized to reduce energy consumption while maintaining high-precision cutting results. Other strengths of the gabbiani af range include simplified machine maintenance and maximum operator safety.

In edgebanding, flexibility will be the keyword across the showcased solutions such as stefani m, new edgebander equipped with servo-assisted operating units that ensure precision and ease of use. The ‘Multiedge’ system enables extremely fast, error-free changeovers with a single click. State-of-the-art edge-gluing technologies further expand finishing possibilities for small and medium-sized manufacturers.

Also in evidence celaschi p20, new automatic double-end tenoner, the most compact in the range. Together with celaschi p30, it stands out for high productivity and precision, ideal for small and medium-sized enterprises producing wooden panels and alternative materials for construction, insulation, industry, doors and solid wood components. Whether used as a stand-alone machine or integrated into a production line, it ensures maximum application flexibility. Intuitive and comprehensive process control provided by the Maestro active square HMI software.

Windows and doors and solid wood processing

For the first time the windor nt1 angular machining center will feature the new ‘Optima BR’ drilling-routing unit, which allows to carry out all complementary machining, including horizontal milling, and the innovative Maestro active windoor software interface. Also in the spotlight is superset nt: the automatic throughfeed moulder equipped with the new electronic control including the ‘eye-S’ console fitted with 10” color touch-screen display and the Maestro active 4-side software, for the machining of profiles for windows, doors, stairs, beads, frames and furnishings.

Timber construction

SCM will present – in an immersive digital experience – the new area gl, 5-axis CNC machining center, engineered to ensure high performance, precision and reliability in the machining of straight and curved glulam elements intended for public building roofs, multi-storey buildings and infrastructure projects. Key features include a work area up to 5×50 meters and the possibility to perform pendulum machining thanks to exclusive mobile fences. Programming and control are managed through the innovative CAM Maestro lab beam&wall and SCM’s Maestro active HMI.

Finishing solutions

The focus of the area dedicated to surface finishing will be the matt effect, a continuously growing trend in the furniture world. Superfici will unveil Supermatt, a new physical matting system capable of achieving ultra-low-gloss finishes with a velvety tactile effect and outstanding durability. Simple, high-performing, and accessible, the new system ensures reduced operating costs and easy integration even into existing lines, with a limited investment. Physical matting becomes straightforward and expands the aesthetic possibilities of coated surfaces, increasing production flexibility. The system is fully compatible with roller, curtain coater, or spray applications.

Joinery machines

Visitors can also explore nova si 4, the most versatile circular saw in its category, featuring a new highly reliable sliding carriage – guaranteed for 10 years – and extensive customization possibilities according to specific application needs. L’invincibile si 3bo will also be present: a circular saw equipped with the innovative ‘blade off’ safety system, which minimizes intrinsic risks through an intelligent detection system and an efficient blade-exclusion mechanism.

Aluminium machining

For the first time on display at the Technology Center in Rimini, the MC 307 Falcon by Mecal Machinery, a Group company. This 4-axis machining center for aluminum, PVC, and steel profiles ensures high precision and productivity. It is the fastest in its class (up to 150 m/min) and stands out for its flexibility in machining aluminum profiles for both fenestration applications (doors, windows, façades) and furniture components (kitchens, wardrobes, office partitions, etc.).